The Humidicore™ should not exhibit external leaks from the case. Should such leaks occur, the cause may be cut or worn “O” rings or loose fasteners. A small amount of shaft seal leakage may occur and is normal. However, excessive venting indicates a worn seal and will require a replacement seal and shaft re-surfacing.

The Humidicore™ internal face seals are designed to reduce the leakage from the fresh side to the exhaust side. Cross-over leakage in this mode consists of two components:

The crack flow component predominates, especially in the smaller wheels, but the pumpover component is noticeable in the 8 inch diameter units. It is a direct function of the core size, speed and pressure differential and can account for a third of total leakage.

The total cross-over leakage specifications for the various cartridge sizes are as follows, at 40 rpm and 3 psid (0.2 bar):

The seal system is designed for a 5 psi (0.3 bar) differential.

How Humidicore™ Works

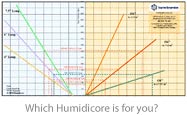

Picking the Right Size

Cartridge Details

Manifold Design

Motor Options

Leakage Considerations

Installation Considerations

Field Service

The Humidicore™ was recently selected as one of R&D Magazine's top 100 Most Technologically Significant Inventions of the Year.