Humidicore is currently in use or test by 23 top fuel cell companies. Over 400 produced, over 230 in field applications and over 100,000 hours of operation so far!

The following are the conclusions drawn from our performance testing:

1. Enthalpy wheel humidification energy is essentially free.

•Higher stack operating temperatures are entirely practical.

•Higher stack operating temperatures yield higher quality cogen heat.

•Higher inlet dewpoints may extend stack life.

2.Enthalpy wheel humidifiers are efficient, compact and inexpensive.

•Avoid complex, expensive internal humidification schemes.

•Avoid larger, less efficient membrane humidifiers.

3.Enthalpy wheel humidifiers have a very low pressure loss.

•Cut compression costs.

•Increase stoichiometric ratio.

4.Enthalpy wheel humidifiers are multi-functional

•Eliminate the aftercooler.

•Eliminate the condenser.

5.Enthalpy wheel humidifiers don’t use liquid water.

•Eliminate humidifier freeze-up.

•Stack Coolant need not be water

6.Enthalpy wheel humidifiers have low thermal inertia.

•Simplify and accelerate start-up sequence.

•Transient operation isn’t a problem.

7.Enthalpy wheel humidifiers are in mass production.

•Common materials and components

•The rotor is an automotive catalytic converter!

How Humidicore™ Works

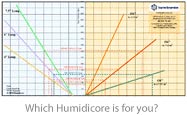

Picking the Right Size

Cartridge Details

Manifold Design

Motor Options

Leakage Considerations

Installation Considerations

Field Service

The Humidicore™ was recently selected as one of R&D Magazine's top 100 Most Technologically Significant Inventions of the Year.