The Humidicore™ may be removed for cleaning with warm water. This is best done by removing the manifolds, to avoid damage to the motor and to allow for a better inspection.

The only field adjustment that can be made is to adjust the tension in the four tierods. These rods control the tension on the end face seals. As the seals wear, internal springs maintain the seal pressure. However, as the unit gets older, it may be necessary to tighten the tie-rods to maintain a low seal leakage rate.

While you have the manifold off, use a torque wrench to turn the core slowly. The 4” diameter units should require about 10 in-lbs (1.1 n-m); the 6” units about 15 in-lbs (1.6 n-m) and the 8” units about 15-20 in-lbs (1.6-2.2 n-m). If wear is excessive, the torques will be lower than specified and the tie-rods may require adjustment if cross leakage is above specifications. It is common to find an “experienced” unit that has a low torque but excellent leakage characteristics. If leakage is a problem, loosening the lock nuts and tightening the tension nuts evenly will re-establish the correct torque. Be sure that the top and bottom end plates remain parallel within ±0.005 inches (±0.13mm). When the turning torque is correct, tighten the lock nuts to prevent further movement.

How Humidicore™ Works

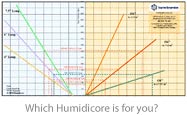

Picking the Right Size

Cartridge Details

Manifold Design

Motor Options

Leakage Considerations

Installation Considerations

Field Service

The Humidicore™ was recently selected as one of R&D Magazine's top 100 Most Technologically Significant Inventions of the Year.